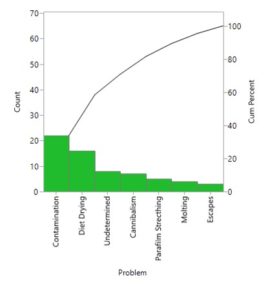

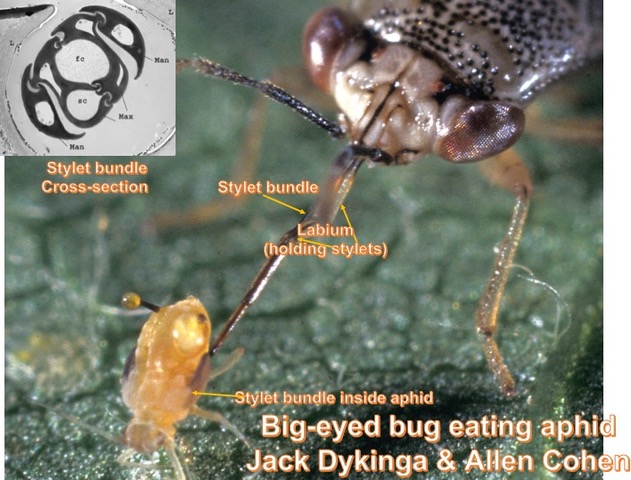

Figure 1: From the Case Study I Developing Predator Diets and the Concept: “KNOW YOUR INSECT.” Using discovery/inquiry to develop and improve rearing systems.

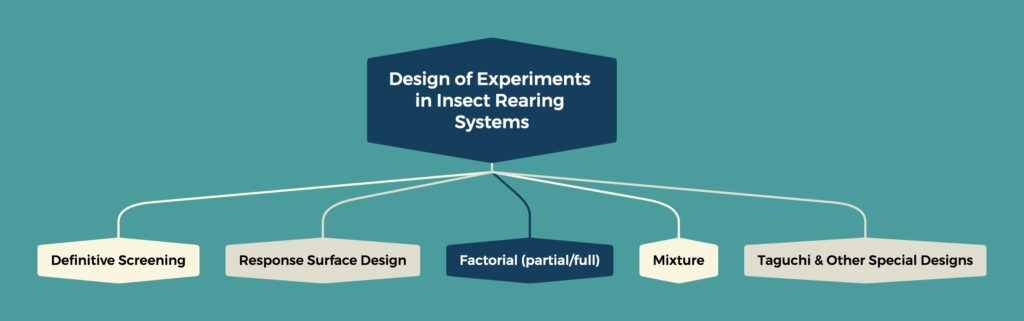

Figure 2 : From Case Study II Using Experimental Designs to Explore Relationships in Insect Rearing Systems.

- October 28, 2025: Introduction: Case study—developing predator diets; why we rear insects (several case studies); sustainability & quality of reared insects; reduction of error and variability in rearing systems

- October 30, 2025: Interactions and importance of rearing system components: using statistically based design of optimization experiments

- November 4, 2025: Nutrition and dietetics in rearing systems

- November 6, 2025: Approaches to quality control and process control (QC & PC)

- November 11, 2025: No Class: Veterans’ Day Holiday

- November 13, 2025: The nature and importance of stresses in rearing systems

- November 18, 2025: The science and technology of equipment in rearing systems

- November 20, 2025; Genetics and epigenetics in rearing systems

- November 25, 2025; Microbial relations and invasive organisms in rearing systems

All classes start at 10:00 am Eastern Time through 1:00 pm Eastern Time. In each class meeting we will have two group discussion of 10-15 minutes to allow questions and contributions from and by participants. The registration fee is $450 for the 24 hours of instruction.

This class is substantially revised and offers up-to-date information about all major aspects or components of insect rearing systems. The content is rich in explanations and guidance to developing standard operating procedures with a scientific basis. The importance of stress is emphasised and quality and process control are key components. The scope of the class is suitable for novices in insect rearing through intermediate levels of background. There is also ample opportunity for participants to individualise their learning experience to meet their current needs and interests.

Please Note: We have greatly increased the interactive opportunities in this course to encourage participants to explore with Professor Cohen special interests from each person’s rearing interests.

To inquire further about the course, contact Professor Allen Carson Cohen at accohen@ncsu.edu

For registration information, please contact

https://reporter.ncsu.edu/link/courseview?courseID=MCE-OPD-C-OLFIRSF&deptName=MCE.

Ms. Darthea Powden

Program Assistant

NC State Continuing and Lifelong Education

Office of Professional Development

Campus Box 7401

Raleigh, NC 27695

919-515-9092 (office)

919-515-7614 (fax)

OR, you may contact

Jamie Merritt

Program Coordinator,

NC State Continuing and Lifelong Education

Office of Professional Development

NC State University

Campus Box 7401

Raleigh, NC 27695

Direct line: 919-515-4796